Until a few years ago, 3D printing was seen as a technology limited to small prototypes or lightweight parts. However, the industrial reality has shifted: today, everything from casting moulds and aerospace components to urban sculptures and architectural structures is being printed. Behind this quiet revolution stands an unexpected protagonist: refurbished industrial robots, transformed into large-format 3D printers.

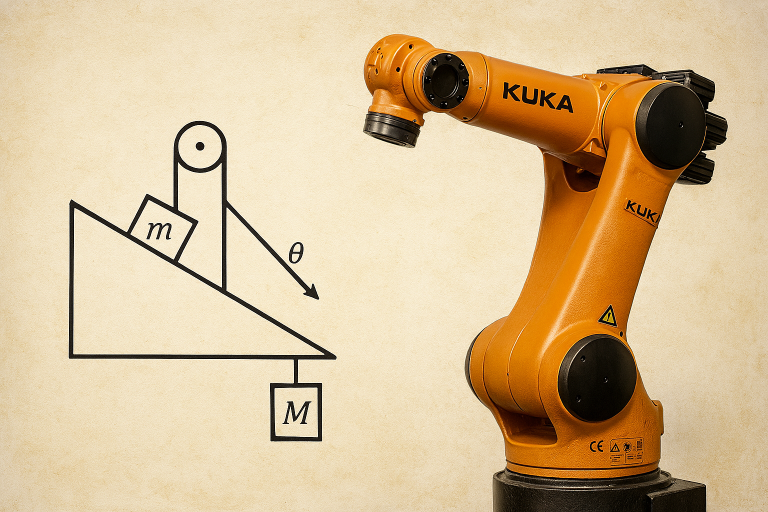

Large-Scale Additive Manufacturing (LSAM) combines the flexibility of six-axis robotic arms with extruders or deposition systems capable of printing plastics, metals, concrete, or composite materials. In this context, refurbished robots from ABB, KUKA, FANUC, and Yaskawa have become an affordable and robust solution for universities, architects, designers and manufacturers who wish to produce at scale without investing in brand-new machinery.

Across Europe, various architectural practices and digital fabrication labs are already using refurbished robots for such projects. For example, the Institute for Advanced Architecture of Catalonia (IAAC) has employed refurbished KUKA arms to print clay and bioplastic structures. In Germany, a research team at the Technical University of Munich (TUM) adapted a refurbished ABB IRB 6700 with a cement extrusion system to print experimental modular walls. These cases show that industrial precision and the low cost of refurbished equipment make for an ideal combination for architectural innovation.

In the mould and manufacturing sector, robotic 3D printing with refurbished robots is being used to create patterns, prototypes, and large-scale components without resorting to CNC milling. For instance, a refurbished FANUC M-710iC can be fitted with a polymer extrusion nozzle to deposit material layer by layer over a work surface of several cubic metres. This approach enables the rapid creation of casting moulds, aerospace parts, or automotive structures with less material waste and in record time.

Beyond the economic savings—up to 60% compared to new systems—refurbished robotics offers a crucial advantage: total flexibility. The same robot that prints bioplastic structures today can, with a simple tool change, mill, polish, or paint the finished model. Such versatility increases the return on investment and reduces the need to purchase multiple specialised machines.

The combination of 3D printing and refurbished robotics is also inspiring new artistic expressions. Contemporary sculptors and digital art studios are using refurbished Yaskawa GP12 and KUKA KR 60 arms to create large-scale works with geometries impossible to achieve by hand. Art, engineering and programming merge into a single language: that of controlled movement and repeatable precision.

From an environmental perspective, robotic 3D printing with refurbished robots also represents a sustainable model. It enables local manufacturing, reduces material waste, and reuses existing industrial equipment, extending its useful life and lowering the carbon footprint associated with producing new machinery.

The conclusion is clear: refurbished robotics is democratising large-scale 3D printing. It is no longer a technology reserved for major laboratories, but a real tool for architectural studios, design workshops, universities, and innovative manufacturers.

At RHTS, we refurbish and certify ABB, KUKA, FANUC and Yaskawa industrial robots, ready to be integrated into 3D printing, machining, or advanced digital manufacturing systems. Our goal is the same as those building the future: to create more, waste less, and build intelligently.