In the lush forests of upstate New York, the architectural and research studio HANNAH—led by Leslie Lok and Sasa Zivkovic, both professors at Cornell University—has taken a bold step toward the future of sustainable construction. Through their project Ashen Cabin, the team explores an experimental integration of 3D concrete printing, robotic milling, and the reuse of natural materials, opening up new possibilities for building with a technological and environmentally conscious approach.

The project was born from an ecological crisis: the devastation caused by the emerald ash borer, an invasive insect that has destroyed millions of ash trees across the United States. Rather than discarding these dead trees, HANNAH transforms them into architectural material, turning forest waste into structural and aesthetic components through advanced technologies. Ashen Cabin is a striking example of how ecological challenges can inspire creative architectural solutions.

At the heart of the project is a hybrid construction system that combines two digital fabrication techniques. The base, plinth, and chimney of the cabin were created using a 3D concrete printer developed by Cornell’s Robotic Construction Laboratory (RCL). This method reduces the need for formwork, minimizes material waste, and allows for complex geometries and faster, more precise construction.

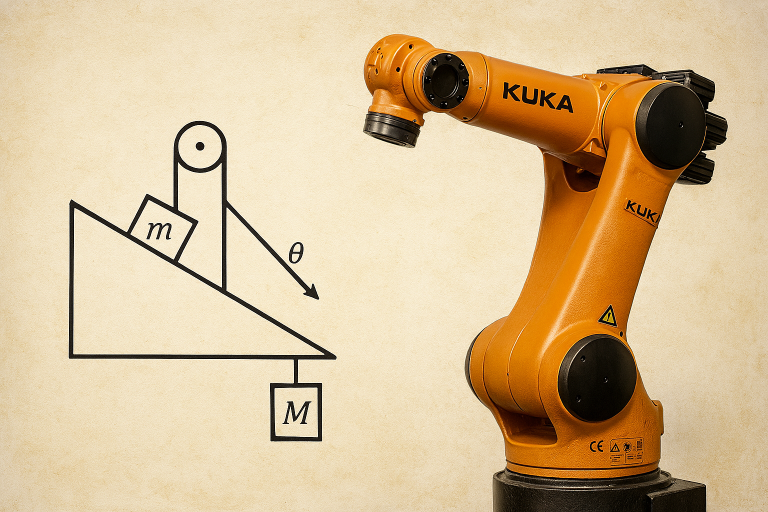

To process the irregular ash logs, the team employed a KUKA KR200/2 industrial robot—originally designed for heavy-duty tasks in industrial settings—which they repurposed for CNC milling. Acquired for just around $8,000 through an eBay auction, the robot exemplifies the economic viability of adaptive robotics in experimental architecture. Each log was 3D scanned to generate a point cloud, enabling the software to guide the milling process while respecting the wood’s natural imperfections. The result is a unique, organic façade that could not be replicated by conventional means.

What makes Ashen Cabin truly innovative is not just its appearance, but the process behind its creation. The flexibility of the KUKA robot to work with irregular geometries challenges the traditional industrial emphasis on standardization. Instead, it introduces a new paradigm in which robotics adapts to natural variability rather than eliminating it. By combining scanning technology, parametric modeling, and robotic milling, the team was able to work with wood that would otherwise be considered unusable, significantly reducing the carbon footprint of the construction process.

The cabin’s aesthetic is a direct expression of its making. The layered textures of the 3D-printed concrete and the irregular contours of the ash wood façade reveal the story of their fabrication. Every detail is a visible testament to the intersection of dead nature and machine intelligence.

Ultimately, Ashen Cabin is more than just an experimental micro-dwelling—it is a critical and forward-thinking proposal that addresses today’s environmental and technological challenges through a deeply investigative architectural lens. By combining robotic automation with sustainable design, the project demonstrates that innovation and expression need not be sacrificed for efficiency. Instead, it envisions a future of architecture that is not only more efficient, but also more attuned to materials, context, and the expressive potential of machines.