Additive manufacturing is rapidly transforming the landscape of modern industry, and KUKA—alongside HS Automation—is leading this shift through cutting-edge solutions for metal 3D printing. This technology stands out for its remarkable blend of robotic precision, energy efficiency, and design freedom, redefining the traditional standards of industrial production.

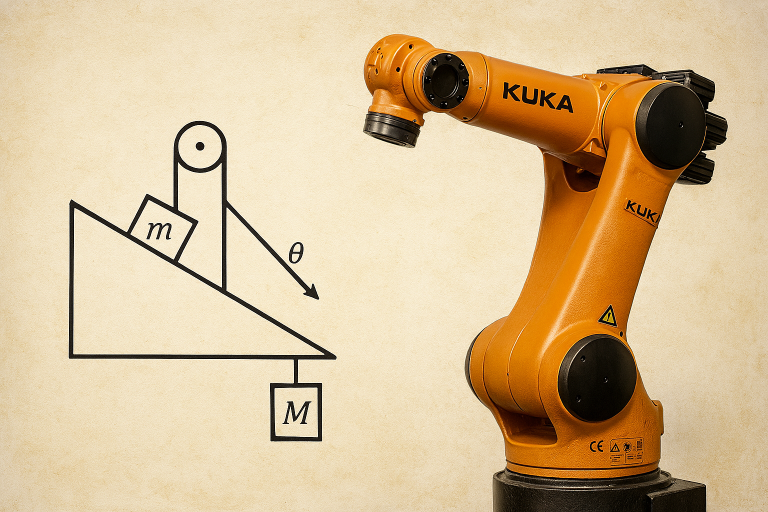

At the center of this innovation is a laser-based manufacturing cell that merges KUKA’s KR IONTEC robot with HS Automation’s DKP-400 V2 tilt-rotation table. Unlike conventional laser sintering techniques, which require support structures to manage overhangs, this system offers a smarter approach: the robotic arm and rotating table work in perfect harmony, welding layer by layer onto the workpiece without the need for metallic powder or support elements. This streamlined method not only simplifies the production process but also enables the creation of larger and more complex components with ease.

The versatility of this technology is another standout feature. It can handle a wide spectrum of metals—from stainless steel and titanium to Inconel and structural steel—and ongoing development is pushing the boundaries further, with copper 3D printing on the horizon. This opens up promising applications across various sectors, including electromobility and medical devices. Moreover, the capability to fabricate bionic structures and internal cooling channels unlocks exciting possibilities in lightweight construction, rapid prototyping, and customized spare part production. For small and medium-sized enterprises, these innovations offer a gateway to high-performance yet sustainable manufacturing practices.

Efficiency and sustainability are woven into every aspect of this process. Laser deposition welding significantly boosts productivity—up to four times compared to traditional methods like milling or turning. Additionally, it reduces material waste by as much as 98%, lowering both environmental impact and production costs. Thanks to its precision, the system achieves fine wall thicknesses of just 2 mm, ensuring optimal mechanical performance in every printed piece.

To make the adoption of this technology as seamless as possible, KUKA has developed the intuitive KUKA.CNC software. This platform allows designs created in CAD or CAM environments to be executed directly by the robot, eliminating the need to translate files into KUKA’s native programming language. As a result, implementation is faster and more user-friendly—especially important for SMEs that may lack specialized programming expertise.

Since 2017, the collaboration between KUKA and HS Automation has continued to evolve, pushing the boundaries of additive manufacturing with each new development. Their solutions are now being tailored for a variety of demanding industries such as automotive, aerospace, and healthcare, laying the groundwork for a new era of metal component design and production. In essence, this partnership is redefining the limits of what metal 3D printing can achieve, offering an unmatched combination of adaptability, reliability, and innovation that speaks to the needs of a fast-changing industrial world.