News - Robotic NEWS about the milling artistic world

- Discover More Insights

Until recently, the idea of robots designing fashion or algorithms choreographing dance routines seemed like something out of science fiction. Today, it is a reality. Artificial intelligence (AI) and robotics are making their mark on traditionally manual industries such as textiles and the performing arts, redefining the boundaries between creativity, efficiency, and technology. And this is not just about automation—we are talking about machines that collaborate, learn, and even create.

A Silent Revolution in Textiles

One of the most significant transformations is occurring in the textile industry. Quality control, once a labor-intensive and error-prone task, has been revolutionized by AI-powered computer vision systems. These systems continuously scan fabrics in real time, detecting flaws that human eyes might miss, ensuring a level of precision and consistency that was previously unattainable.

Maintenance has also evolved. Modern textile machinery is now equipped with sensors that collect data continuously. AI algorithms analyze this data to predict when maintenance will be needed, preventing unexpected breakdowns and extending the lifespan of equipment.

AI is also reshaping supply chains. By analyzing historical data, consumer trends, and external factors such as weather or global logistics, AI can forecast product demand with remarkable accuracy. This leads to less waste, reduced inventory, and greater agility in responding to market changes.

In the realm of design, AI has become a creative partner. Tools like Adobe Textile Designer and services like Stitch Fix use trend data and consumer preferences to generate visual proposals or recommend personalized garments. These technologies do not replace designers but provide them with a more refined canvas aligned with market tastes.

Sustainability Begins at the Factory

With increasing pressure on the fashion industry to become more sustainable, AI has proven to be a key ally in reducing waste and optimizing processes. For example, the Lectra Vector system maximizes fabric usage during cutting, while Alchemie Technology’s AI-assisted dyeing process can reduce water consumption by up to 95%.

Robots That Can Sew

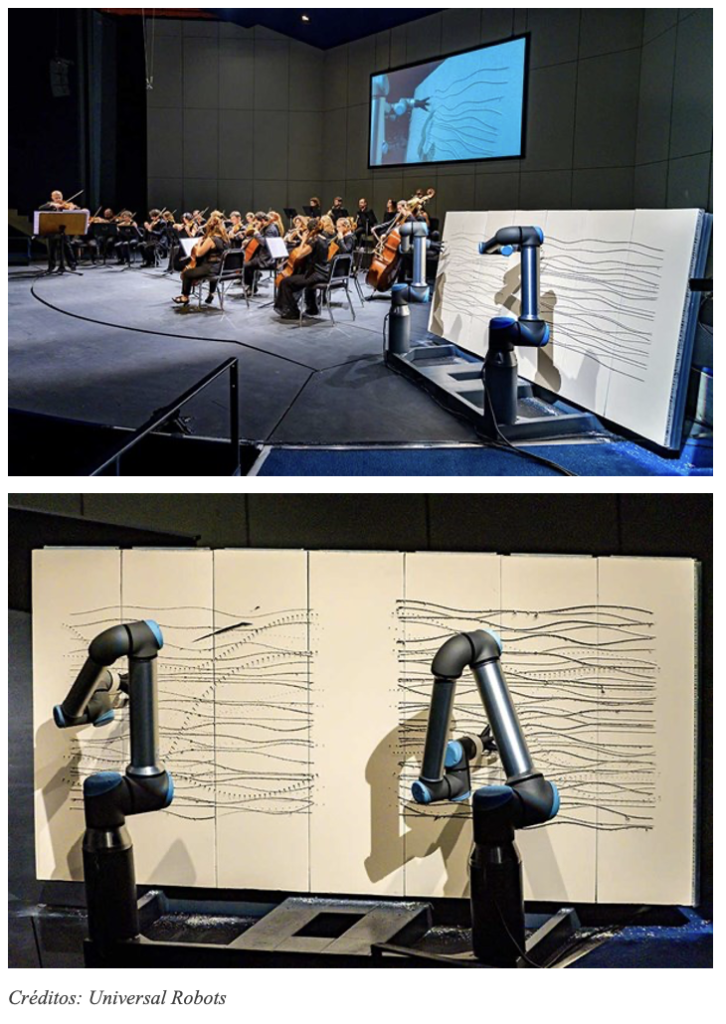

A fascinating real-world example is the Sewbo system, which uses a collaborative robotic arm (UR5 by Universal Robots) to sew garments. The trick lies in temporarily stiffening fabrics with a water-soluble polymer, allowing the robot to handle them as if they were plastic. After sewing, the garments are washed to restore their original texture. This innovation offers a glimpse into the future of automated garment production—efficient, precise, and less reliant on intensive manual labor.

The Future Is Already Underway

The fusion of AI, robotics, and creativity is no longer a distant promise—it is happening now in factories, studios, and theaters around the world. For many companies, this transformation represents a strategic opportunity to enhance competitiveness, quality, and sustainability.

But beyond efficiency, what is truly inspiring is how these technologies are expanding the realm of the possible. Designers are working hand-in-hand with algorithms, robots are helping tell stories on stage, and machines are sewing with the precision of master artisans.

Now is the time to imagine not just how to produce faster, but how to produce better—and, why not, more creatively.

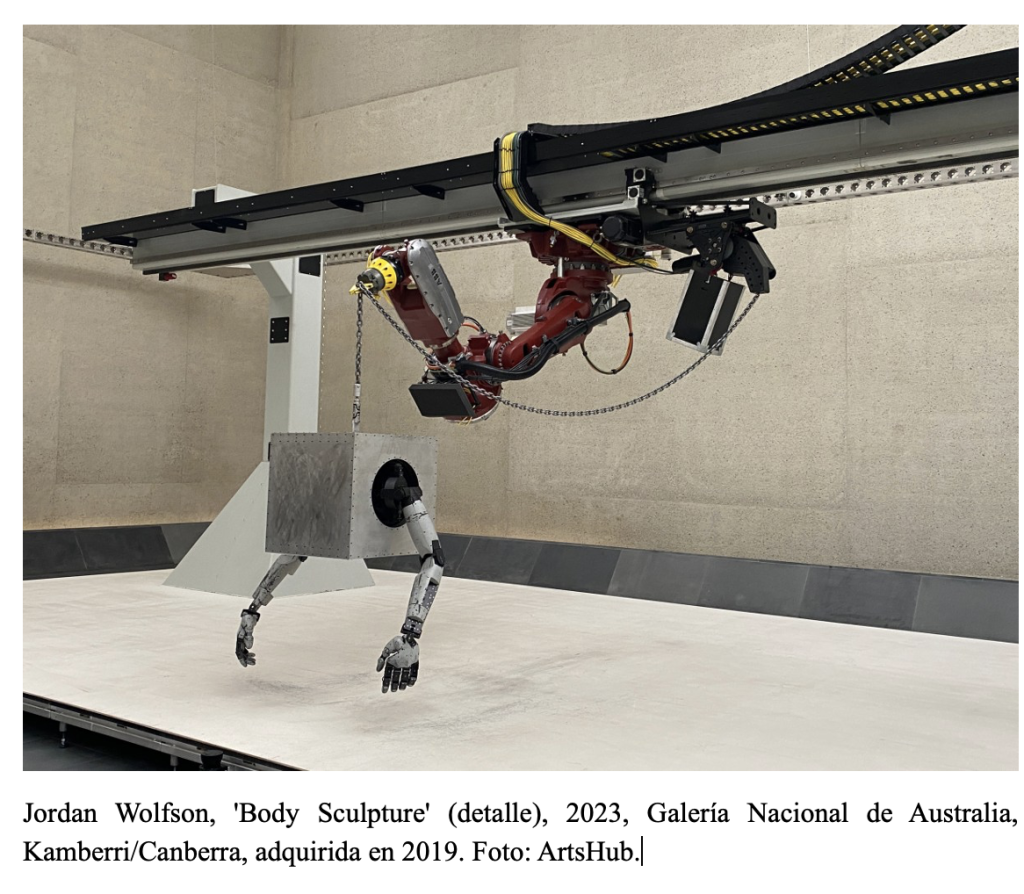

In the contemporary art world, where disciplines intersect and the boundaries between the mechanical and the human dissolve, Jordan Wolfson’s new work, Body Sculpture, emerges as a piece that redefines what sculpture can be in the digital and automated age.

Unveiled at the National Gallery of Australia (NGA), this robotic work is much more than a visual experiment: it is a sensory and intellectual experience built from mechanical precision and conceptual sensitivity. Valued at 6.67 million Australian dollars, Body Sculpture integrates advanced automation engineering, sculpted metal structures, and a sophisticated kinematic control system.

Technology Applied to Art: Beyond Performance

The installation consists of a steel block with two articulated arms, suspended by a chain from an industrial robotic arm. The movement is not random: it is programmed with a 30-minute choreography designed to evoke human emotions, from fear to empathy.

This project was developed in collaboration with technologist Mark Setrakian, an expert in animatronics and special effects with experience in films such as Hellboy and Men in Black. The movement system uses kinematic interpolation algorithms, combining hydraulic systems and electric motors to simulate organic movements with millimetric precision.

For those working with techniques like CNC milling, the logic behind Body Sculpture is familiar: it is a sculpture generated and controlled by an automated system that translates digital information into movement and physical form. But what sets this piece apart is its ability to express, not just execute.

Technical Components of Body Sculpture

Industrial Robotic Arm

The sculpture is suspended by a chain connected to a large industrial robotic arm, similar to those used in the automotive industry. This arm is mounted on a steel structure that allows horizontal and vertical movements, enabling complex and precise choreography.

Metal Cube with Articulated Arms

The central element of the sculpture is a metal cube, approximately the size of a clothes dryer, made of aluminum and aerospace-grade plastics. Two humanoid arms with oversized hands emerge from this cube, capable of detailed and expressive movements.

Adaptive Control System

The sculpture’s movement is managed by an adaptive control system developed by robotics expert Mark Setrakian. This system allows real-time adjustments during performances, using sensors to meticulously track and correct movements.

Specialized Collaborations

In addition to Setrakian, the project involved Richard Taylor, co-founder of Wētā Workshop, as well as professionals in musical composition, acting, and choreography. These collaborations enriched the performative and emotional dimension of the work.

Technical Design and Functionality

The sculpture performs for approximately 30 minutes, divided into three acts that combine gentle and violent movements, evoking human emotions such as vulnerability, sensuality, and despair. The movements are programmed to simulate human gestures, such as hugging itself or striking the ground, creating an immersive experience for the viewer.

The sound system reaches levels of up to 100 decibels, incorporating percussion effects and mechanical noises that intensify the sensory experience.

A Work That Questions the Viewer

Unlike previous works such as Female Figure or Colored Sculpture, which explored violence, sexualization, and fetishism, Body Sculpture addresses human vulnerability. The sculpture does not represent a body, but its movements echo our own. The chain that holds it suggests submission or control, but also support and connection.

Each session requires the audience to remain silent and wear earplugs, as the sound and force of the movement reach high levels. The viewer does not observe a passive work: they confront a presence. And that presence moves, falls, recoils, trembles. As if it were thinking. As if it were feeling.

Implications for Sculptors and Digital Artists

For sculptors working with industrial robots, parametric modeling, or automated prototyping, Body Sculpture is a case study. Not only for its technical execution, but for the way it transforms a robotic arm—traditionally associated with mechanical production—into an expressive, even vulnerable, entity.

The sculpture becomes a medium that shapes not only matter, but also emotion. Wolfson’s challenge is direct: Can a machine represent the human condition without a body, a soul, or a face?

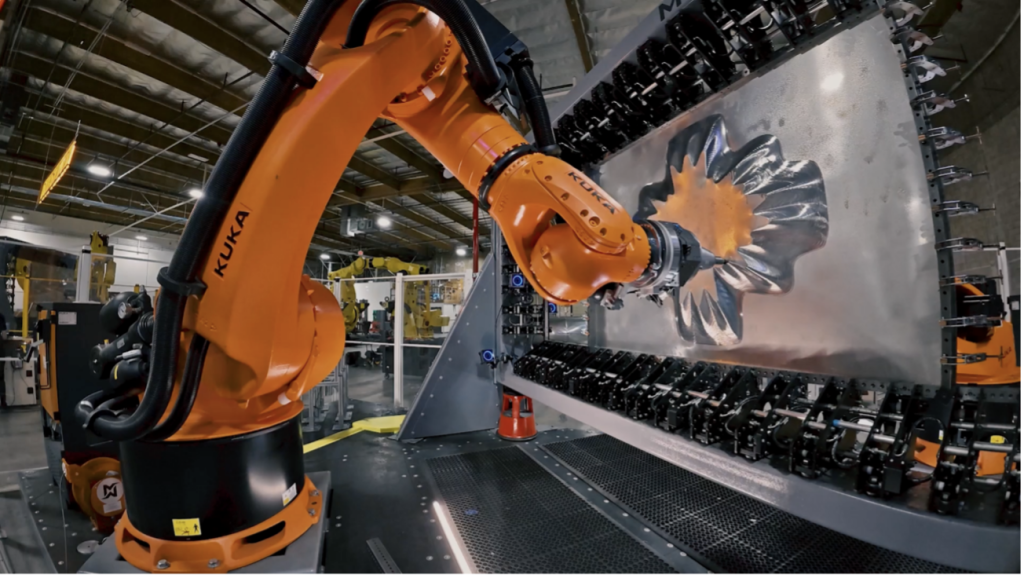

In recent years, industrial automation has seen remarkable advancements, and welding is no exception. KUKA, a leader in robotic solutions, offers a range of welding robots with protective gas that stand out for their precision, efficiency, and adaptability, catering to the diverse needs of modern industry.

Versatility in Models for Various Applications

KUKA provides a wide array of robots specifically designed for protective gas welding processes, which adapt to various load and reach requirements:

KR CYBERTECH nano ARC: Specialized in protective gas welding, it offers a load capacity of 6 to 8 kg and reaches between 1440 and 1840 mm. Its hollow wrist design allows optimal accessibility during welding.

KR CYBERTECH nano: With a load capacity of 6 to 10 kg, this model features a slim central wrist that facilitates the mounting of triangulation sensors for seam processing.

KR AGILUS: Compact and lightweight, with load capacities of 6 to 10 kg and reaches of 700 to 1100 mm, it is ideal for confined spaces and TIG welding applications.

KR CYBERTECH: With a load capacity of 8 to 22 kg, it is perfect for heavy welding equipment or additional sensors.

KR CYBERTECH ARC: With a load capacity of 8 kg and a reach of 2100 mm, it is ideal for welding large metal components.

KR IONTEC: Designed for applications requiring large reaches (up to 3100 mm) and significant load handling (from 20 to 70 kg), such as welding large components or heavy welding equipment.

Advanced Software for Precise and Efficient Welding

The integration of specialized software is key in KUKA robots:

KUKA.ArcTech: Facilitates the programming and handling of arc welding tasks through intuitive instructions and structured menus.

KUKA.ArcSense: Analyzes real welding parameters and automatically compensates for tolerances, ensuring the quality of the welded seam.

KUKA.ArcTech AdaptiveWelding: Automatically adjusts welding parameters to component tolerances, maintaining consistent quality.

KUKA.SeamTech Finding and Tracking: Uses laser sensors for detecting and tracking weld seams, adjusting the trajectory in real-time.

KUKA.TouchSense: Adjusts for variations in shape and position of parts by taking measurements before welding.

KUKA.Tracc TCP: Automatically verifies and adjusts the tool center point (TCP) to ensure maximum precision in welding operations.

KUKA.Sim: Allows offline programming of welding installations, facilitating the simulation and creation of robot sequences.

Integration and Compatibility with Existing Systems

KUKA robots easily integrate with welding sources from various manufacturers such as Binzel, ESAB, EWM, Fronius, Kemppi, Lincoln, Lorch, Megmeet, Migatronic, Miller, or SKS. This compatibility is achieved through fieldbus interfaces like EtherCAT, ensuring efficient communication and minimizing startup times.

Applications in Modern Industry

KUKA's protective gas welding robots are widely used in various industries, including automotive, where they are employed in manufacturing components like frames and battery housings for electric vehicles. They are ideal for several industrial applications due to their adaptability to processes such as MIG/MAG, TIG, and plasma.

The range of protective gas welding robots offered by KUKA constitutes a comprehensive and advanced solution for the automation demands within modern industry. With a combination of robust hardware and advanced software, these robots offer precision, efficiency, and adaptability, significantly contributing to the improvement of welding processes in various industrial applications.

- About Us

Robotic Hi-Tech Solutions provides innovative robotic machining solutions that enhance productivity, precision, and performance globally.

- Contact Us

- Information

- Helpful Links

- Stay Updated

Subscribe to our newsletter and be the first to discover the latest in robotic machining, industry insights, and exclusive updates.