In the contemporary art world, where disciplines intersect and the boundaries between the mechanical and the human dissolve, Jordan Wolfson’s new work, Body Sculpture, emerges as a piece that redefines what sculpture can be in the digital and automated age.

Unveiled at the National Gallery of Australia (NGA), this robotic work is much more than a visual experiment: it is a sensory and intellectual experience built from mechanical precision and conceptual sensitivity. Valued at 6.67 million Australian dollars, Body Sculpture integrates advanced automation engineering, sculpted metal structures, and a sophisticated kinematic control system.

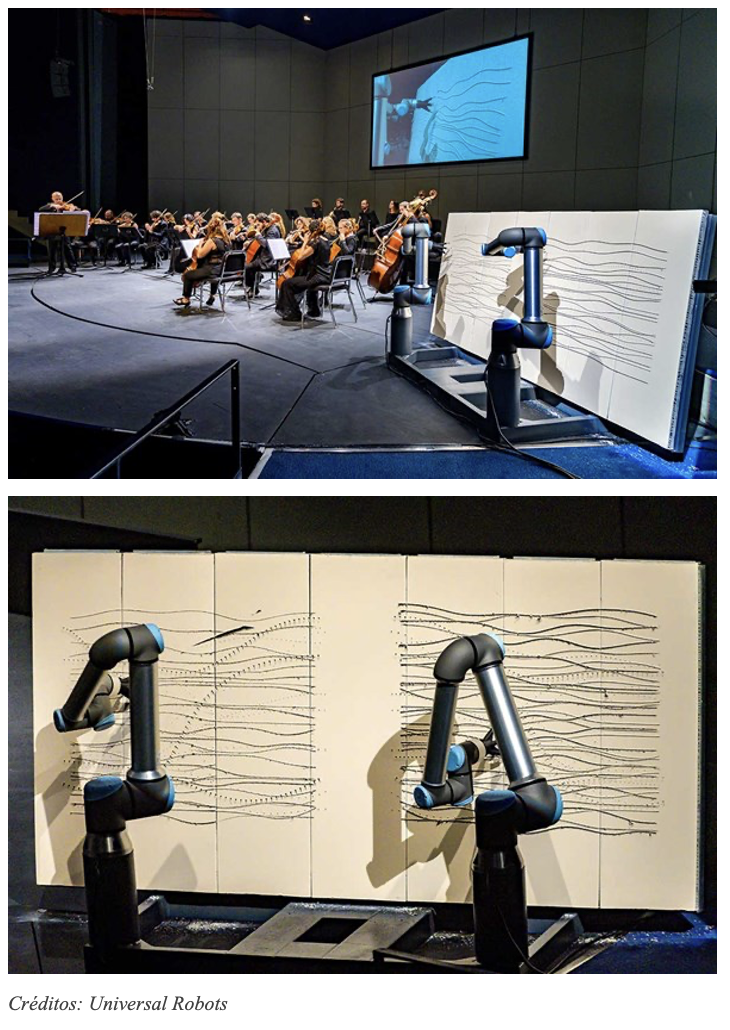

Technology Applied to Art: Beyond Performance

The installation consists of a steel block with two articulated arms, suspended by a chain from an industrial robotic arm. The movement is not random: it is programmed with a 30-minute choreography designed to evoke human emotions, from fear to empathy.

This project was developed in collaboration with technologist Mark Setrakian, an expert in animatronics and special effects with experience in films such as Hellboy and Men in Black. The movement system uses kinematic interpolation algorithms, combining hydraulic systems and electric motors to simulate organic movements with millimetric precision.

For those working with techniques like CNC milling, the logic behind Body Sculpture is familiar: it is a sculpture generated and controlled by an automated system that translates digital information into movement and physical form. But what sets this piece apart is its ability to express, not just execute.

Technical Components of Body Sculpture

Industrial Robotic Arm

The sculpture is suspended by a chain connected to a large industrial robotic arm, similar to those used in the automotive industry. This arm is mounted on a steel structure that allows horizontal and vertical movements, enabling complex and precise choreography.

Metal Cube with Articulated Arms

The central element of the sculpture is a metal cube, approximately the size of a clothes dryer, made of aluminum and aerospace-grade plastics. Two humanoid arms with oversized hands emerge from this cube, capable of detailed and expressive movements.

Adaptive Control System

The sculpture’s movement is managed by an adaptive control system developed by robotics expert Mark Setrakian. This system allows real-time adjustments during performances, using sensors to meticulously track and correct movements.

Specialized Collaborations

In addition to Setrakian, the project involved Richard Taylor, co-founder of Wētā Workshop, as well as professionals in musical composition, acting, and choreography. These collaborations enriched the performative and emotional dimension of the work.

Technical Design and Functionality

The sculpture performs for approximately 30 minutes, divided into three acts that combine gentle and violent movements, evoking human emotions such as vulnerability, sensuality, and despair. The movements are programmed to simulate human gestures, such as hugging itself or striking the ground, creating an immersive experience for the viewer.

The sound system reaches levels of up to 100 decibels, incorporating percussion effects and mechanical noises that intensify the sensory experience.

A Work That Questions the Viewer

Unlike previous works such as Female Figure or Colored Sculpture, which explored violence, sexualization, and fetishism, Body Sculpture addresses human vulnerability. The sculpture does not represent a body, but its movements echo our own. The chain that holds it suggests submission or control, but also support and connection.

Each session requires the audience to remain silent and wear earplugs, as the sound and force of the movement reach high levels. The viewer does not observe a passive work: they confront a presence. And that presence moves, falls, recoils, trembles. As if it were thinking. As if it were feeling.

Implications for Sculptors and Digital Artists

For sculptors working with industrial robots, parametric modeling, or automated prototyping, Body Sculpture is a case study. Not only for its technical execution, but for the way it transforms a robotic arm—traditionally associated with mechanical production—into an expressive, even vulnerable, entity.

The sculpture becomes a medium that shapes not only matter, but also emotion. Wolfson’s challenge is direct: Can a machine represent the human condition without a body, a soul, or a face?